Keeping oneself safe and secure is of paramount importance in today’s environment, which is notoriously unstable and full of threats. The need for dependable and effective security is ever-present, whether on the battlefield where troops stay vigilant, or the streets where police officers uphold justice. Bulletproof gear, made of materials like PPTA and steel, has acquired a household name throughout the years, providing a measure of protection that has undoubtedly prevented many deaths. However, as scientific advances proceed, a new player — nanotechnology — has entered the arena. Recent advances in nanoscience have the potential to radically alter the landscape of protective gear by delivering lightweight solutions that compete with and, in some cases, outperform those of traditional materials.

Nanotechnology in Bulletproof Clothing: A Game-Changing Breakthrough

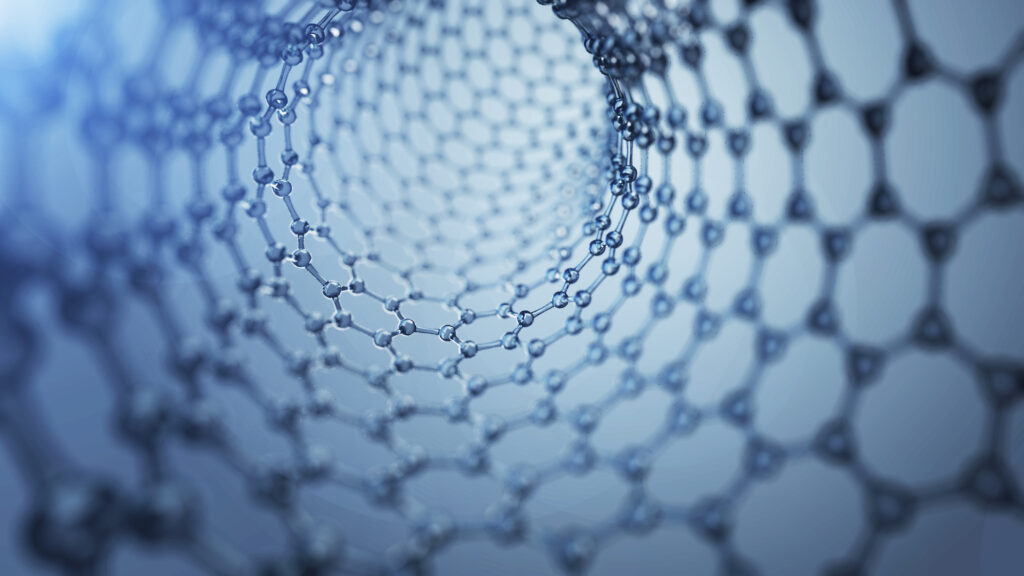

The Institute for Soldier Nanotechnologies (I2N2) at the Massachusetts Institute of Technology (MIT) is at the front of this pending change. These scientists have uncovered a new world of opportunity by tapping into the enormous potential of nanotechnology through their dogged pursuit of knowledge and unflinching willingness to experiment. At its core, this innovative project is built on a material with a lattice-like structure, which was painstakingly crafted using the accuracy of nanotechnologies. The significance of this breakthrough cannot be overstated; tests conducted in a laboratory have shown that a fabric woven using nanotechnology can withstand forces greater than those that can be applied to PPTA or steel.

It is not just the material’s resistance to outside pressures that make it remarkable, but also its remarkable effectiveness in avoiding penetration. When trying to break through the nanotech lattice, you’ll meet stronger resistance than you would from most common substances. With this development, humanity enters a new era in which ultralight body armor, blast shields, and other forms of protective gear are the norm.

Harnessing the Power of Nanotechnology: Unveiling the Lattice Structure

The key to this revolutionary development is a new method of making a lattice-like structure at the nanoscale. This complex dance requires the careful manipulation of a material called “photoresist,” which has the unique virtue of changing shape when exposed to light, usually in the form of lasers. The result of this intricate dance with light is a sort of 3D printing on a scale so small that it defies current methods of production.

The hard shell of a motorcycle helmet is a good comparison for understanding the technique’s far-reaching ramifications. This shell has been painstakingly designed to withstand a particular amount of high-velocity impact before succumbing to strain cracks, as is done in the classical sense. Imagine this identical shell constructed out of an infinite number of microscopic layers, all of which provide a layer of defense. This achievement, which was previously thought to be impossible using conventional methods, is now a palpable reality thanks to the revolutionary potential of nanotechnology. The capability to stack material layers inside a restricted space opens up a world of incredible strength and security.

Nano-Architecture for Impact Mitigation: Redefining Protection

Nanotechnology’s potential applications in the field of safety equipment are truly revolutionary. Researchers have struggled for a long time to find a happy medium between increasing protection and making the gear too heavy to be comfortable to wear. The development of nanotechnology has brought us one step closer to achieving this balance. Once thought to be impossible, scientists are on the cusp of achieving unheard-of levels of security while reducing the burdens placed on soldiers by leveraging the unique qualities of nanotechnology.

Envision a world where soldiers don’t have to sacrifice comfort for safety because their helmets and armor are too heavy. This is not an incremental improvement, but a paradigm change that has the potential to reimagine what it means to be safe under extreme circumstances. The dream of ultra-lightweight body armor and protective gear is becoming a reality as research and technology advance, freeing wearers from having to choose between safety and mobility.

Scaling Up Production: Overcoming Challenges, Embracing Opportunities

However, as is the case with any revolutionary idea, there will be obstacles to overcome. Scaling up production to meet the demands of the real world is a difficult barrier that must be overcome as we move from laboratory wonders to actual field applications. Small amounts of nanotechnology components used in tightly regulated lab settings are insufficient for widespread use. A new ecosystem of manufacturing capacities, novel processes, and possibly paradigm-shifting procedures is required for this transition, rather than merely a series of incremental changes.

But there are endless possibilities inside these difficulties. Nanotechnology’s ramifications aren’t limited to the realm of defense and military use. The findings of this ground-breaking study have the potential to spur improvements in security across a wide range of sectors, from law enforcement to space exploration. In a world full of complexities and uncertainties, nanotechnology can redefine how we understand and attain safety.

A World of Nano-Materials: Beyond Graphene

The field of nanotechnology contains a vast library of untapped materials, each with its potential application in the quest for cutting-edge safety equipment. Graphene, which consists of a single layer of carbon atoms ordered in a hexagonal lattice, is one such substance. The thickness of this two-dimensional marvel is only one carbon atom or about 0.335 nanometers, and it was discovered only a decade ago. As a result of its sp2 hybridized bonds, symmetrical plane structure, and strong covalent bonding, graphene possesses a wide range of unique qualities. Mechanical properties like ultimate strength (130 GPa) and elastic modulus (1 TPa) are also extraordinary, as are the material’s electrical and thermal conductivities.

Graphene Nanoplatelets

Graphene and its derivatives, including multilayer graphene, graphene nanoplatelets (GNPs), and graphene oxide (GO), have been integrated into nanocomposites specifically designed for ballistic impact applications to take advantage of their exceptional features. For instance, multilayer graphene has shown a specific penetrating energy roughly 10 times larger than that of tiny steel sheets, highlighting its potential as a game-changing component in protective gear.

Laminates

In recent efforts, graphene laminates produced from nanoparticles have been inserted between layers of PPTA fibers, dramatically improving the material’s ballistic performance. Material deformation is minimized and stability is improved after ballistic testing thanks to this novel approach. In addition, multilayer graphene/polyethylene (PE) composites’ exceptional anti-ballistic performance has been further investigated by molecular dynamic simulations. According to the results, the ballistic impact resistance of PE that has been covered by a single layer of graphene membrane is significantly increased, by more than a factor of eight. Potentially protecting against hypersonic collisions is the allure of multi-layered graphene/PE nanocomposites.

Graphene Oxide

Although graphene alone has some intriguing properties, it is graphene oxide (GO) that has attracted the most attention due to its remarkable surface adherence with polymer matrices. Because of its oxygen-containing groups and amphiphilic structure, GO is chemically reactive and readily incorporates polymer fibers. To this end, GO has quickly become a go-to for improving the mechanical and ballistic properties of a wide range of fiber-based polymer composites.

Nanoclay

In addition to graphene, nanoclay is another promising nanotechnology material. Nanoclay, which is made up of layers of mineral silicates, has a remarkable aspect ratio due to its inherent sheet structure. Because of its unusual structure, nanoclay can be used as a reinforcement filler in fiber-based polymer composites, where it can replace more expensive organic nanofillers. Nanoclay promotes superior mechanical and ballistic performance in these composites by exploiting the principles of Van Der Waals forces. Recent studies have revealed that adding nanoclay to polymer composites significantly increases their stiffness, strength, hardness, and energy absorption.

Unlocking Impact Resistance with Tungsten Disulfide

Tungsten disulfide is an intriguing thread in the fabric of materials propelled by nanotechnology. Molybdenum disulfide, another inorganic layered nanomaterial, also exists as 2D stacked molecular sheets. Tungsten disulfide’s outstanding properties—including its great chemical stability, ultra-low friction, robust elasticity, and exceptional shock-absorbing capacity—are based on its unique one-layer chemical structure. This material’s resistance to high temperatures and pressures makes it an excellent choice for use in ballistic impact situations.

Nanoparticles of inorganic tungsten disulfide (IF-WS2) and INT-WS2 (inorganic nanotubes tungsten disulfide) have recently been shown to offer promising properties as reinforcing agents in ballistic protection and energy absorption materials. Mechanical characteristics, impact resistance, and deformation under high-velocity impact are all improved because of the incorporation of these nanoparticles. An intriguing peek into the future of protective gear exists thanks to the inclusion of these nanoparticles into fiber-based polymer composites, where the boundaries of protection are extended further than ever before.

Pro Future Tips for Choosing and Using Nanotechnology-Based Protective Gear

Although nano tech is not currently widely available, it’s important to consider what the future holds and ponder on what might be the best solution for your protection needs. Here are some choice future tips to take into account when the time comes to purchase a nano tech-based vest or protective gear:

Understand Your Needs

Once widely available, choose nanotechnology-based protective gear with your needs in mind. Think about things like the types of dangers you might face, how mobile you need to be, and how long you’ll be wearing the gear.

Evaluate Materials

Learn more about the various nanomaterials, like graphene and nanoclay, that are included in safety equipment. Each material has its own set of advantages and disadvantages in terms of durability, weight, and comfort.

Check Certification

Verify if the accreditations and standards recognized by the industry have been met by the protective equipment. To ensure the effectiveness of the equipment, look for labels stating that it complies with safety laws.

Fit Matters

The best possible defense requires a snug fit. To make sure your gear fits tightly without restricting your movement, use the sizing information provided by the manufacturer.

Layer for Maximum Benefit

If you’re concerned about your safety, you could want to combine regular protective gear with that based on nanotechnology. When used together, different types of materials can provide a formidable barrier against numerous dangers.

Maintenance is Key

Take the time to care for your equipment the way it was intended. The protective characteristics and longevity of the equipment are enhanced by routine cleaning and inspection.

Stay Informed

Learn about new developments in nanotechnology and safety equipment. Better methods of ensuring one’s safety may be developed as research progresses. Try to stay up to date with all the improvements in the industry.

Frequently Asked Questions (FAQs) About Nanotechnology-Based Protective Gear

What exactly is protective gear based on nanotechnology?

Nanotechnology-based protective gear uses nanoscale engineering to provide increased safety from hazards including ballistic impacts and chemical exposure. These materials have certain qualities that can make protective gear more efficient and pleasant to wear.

To what extent does nanotechnology improve safety equipment?

Material qualities such as enhanced strength, enhanced energy absorption, and decreased weight are all possible thanks to nanotechnology. As a result, people need clothing and equipment that provide greater security without restricting their ability to move freely.

Is it safe to utilize nanotechnology-based gear for an extended period?

Yes, safety is prioritized in the development of nanotechnology-based equipment. To guarantee that their products are safe for consumers to use, manufacturers must comply with several rules and standards. However, to preserve its protective qualities over time, it is crucial to adhere to the care and maintenance instructions provided.

Can I utilize armor made using nanotechnology for regular tasks?

While nanotechnology-based equipment is now tailored toward high-threat situations, developments in materials science may one day allow for more flexible alternatives. These days, such gear is usually tailored to counteracting certain hazards and isn’t always ideal for general use.

When it comes to nanotechnology-based protective gear, how do I make the best selection?

Think about what you need, how much security you want, and what kinds of dangers you face. Examine the properties of several materials, such as graphene and nanoclay, and decide which ones are most suited to your needs.

When shopping for protective gear based on nanotechnology, what credentials should I look for?

Verify that it complies with all mandatory safety standards by checking for appropriate certificates and labeling. Certifications from groups like the Occupational Safety and Health Administration (OSHA) or the National Institute of Justice (NIJ) may be important depending on the type of equipment.

Can nanotechnology-based gear be used as a substitute for conventional safety gear?

In addition to, or instead of, conventional armor, gear based on nanotechnology can boost safety. Sometimes the best defense is a mix of the two, depending on the nature of the threat and the conditions.

What kind of upkeep is required for nanotechnology-based armor?

Always refer back to the manual for proper upkeep and servicing of the equipment. If you want your protective gear to continue to do its job, you need to keep it clean regularly following the procedures specified by the manufacturer.

Is gear made with nanotechnology acceptable for use in harsh environments?

The enhanced features of nanotechnology-based gear make it ideal for use in challenging environments. However, you must be sure that the equipment has been tried and proven in the environment you will be entering.

When it comes to nanotechnology, what does the future hold for armor?

There is hope for the future of protective gear based on nanotechnology. More improved materials providing remarkable safety, comfort, and adaptability in a variety of settings may be developed as a result of ongoing research and invention.

The Path Ahead: A Future Redefined

As nanotechnology advances in protective gear, a bright future full of game-changing opportunities appears. The convergence of creative thinking and scientific prowess portends a sea change in which lightweight armor finally lives up to its promise of uncompromised safety. Nanotechnology reveals a new world where the concept of personal safety can be applied to a wide range of situations, from military personnel navigating dangerous terrains to first responders facing the unknown.

Nanotechnology’s future in protective gear is promising, with the union of science and innovation promising to radically alter the nature of security and safety. Institute for Soldier Nanotechnologies pioneers have only touched the surface of what is possible, leaving a legacy of possibilities for future generations to study. Shields that can’t be penetrated, body armor that can take a beating, and other forms of unconventional protection may become more commonplace in the years to come.

Combining nanotechnology with the military might show how resourceful and creative humans can be. It echoes a universal truth: there are no limits to creativity when faced with adversity. The way forward in nanotechnology seems clearer than ever as scientists continue to map out uncharted territory. The advent of nanotechnology-driven protective gear heralds a bright future when peace of mind is not just a fantasy but a daily reality.