Bulletproof vests, trusted allies in the quest for security, stand as silent sentinels against the threat of ballistic harm. Curious minds often wonder about the composition of these formidable barriers. Essentially, they are a complex network of bulletproof materials that are engineered to protect the vitals within from the devastating force of bullets. Layers of extremely strong fibers are the main component of bulletproof vests. These fibers absorb and deform the bullet, allowing its energy to be distributed over a large area.

The complex web of these garments that save lives exposes the interaction between technology and science. As a result of an ongoing effort to enhance both protection and comfort, body armor has progressed through the years from simple metal plates to complex composites. Modern vests are a combination of materials, with each fiber chosen for its outstanding strength-to-weight ratio. These materials include Kevlar, Twaron, and Spectra. One example of human resourcefulness in combat is the fact that certain vests use a grid of metal or ceramic plates to deflect bullets at high velocities.

“What Materials Are Used in Bulletproof Vests?” is where we’ll dive headfirst into the meat of our investigation into these protective garments. The careful attention to detail in every stitch and the coordinated action of each layer to avert disaster are revealed to you. The path ahead is filled with gratitude for the hidden craftsmanship that empowers heroes as they navigate their daily dance with fate.

What Materials Are Used in Bulletproof Vests?

Ever wondered what keeps law enforcement and security personnel safe in the line of duty? The complex construction of armored vehicles. Designed for maximum protection, these vests are a combination of clever materials.

- Kevlar is the superstar material in soft body armor, renowned for its strength and ability to absorb impact energy. Since its inception, Kevlar has saved countless lives.

- Ultra-High Molecular Weight Polyethylene (UHMWPE) is another hero in the bulletproof vest saga. Its high performance in the face of danger makes it an excellent choice for personal protection.

- Ceramics and steel often come into play for hard armor plates. These materials are tougher and are used in conjunction with other materials to stop even more lethal ammunition.

If you want to learn more, please click here.

Bulletproof vests, or as the experts term them, ballistic vests, are not crafted from ordinary fabric. They are typically a blend of materials, each with a unique role. Let’s dive into a little more detail:

Kevlar:

- It’s a synthetic fiber, five times stronger than steel on an equal weight basis.

- Kevlar vests in general are lightweight and flexible, providing protection with a minimal form factor and less bulk than other types of vests.

UHMWPE:

- This long-chain polyethylene is used to make hard armor plates.

- It’s resistant to cuts and has a high impact strength.

Ceramics and Steel:

- These are used for plates that can stop rifle rounds.

- Often heavier, these materials are used for tactical operations where higher protection levels are necessary.

| Material | Benefits | Use Case |

| Kevlar | Lightweight, flexible | Everyday law enforcement use |

| UHMWPE | High impact strength, cut-resistant | Hard armor plates |

| Ceramics | High hardness level | Tactical operations against rifle rounds |

| Steel | Durable and strong | High-risk scenarios |

Bulletproof vests have evolved significantly. At Bullet Proof Supply Store, a vest priced at just $299 can halt anything from a BB gun to a .44 Magnum.

Bulletproof vests are not just about stopping bullets. Comfort is a priority too. That’s why vests like the one offered by Bullet Proof Supply Store are concealable, ensuring wearers can go about their daily activities with ease.

Think about how bulletproof vests contribute to your overall security while you marvel at their incredible engineering. How can these vests stop a bullet in their tracks? It’s a combination of natural material qualities and scientific genius.

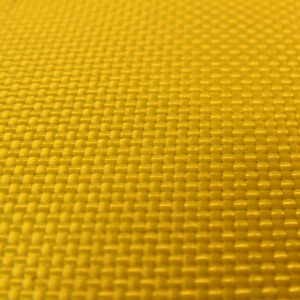

Put yourself in a situation where you’re up against an enemy. All that separates you from danger is the fabric of your vest. The net-like fabric, be it UHMWPE or Kevlar, absorbs and disperses the bullet’s energy, turning a potentially fatal situation into one that can be survived.

The materials utilized in bulletproof vests are truly groundbreaking, as we come to the end of our discussion. It is equally important to think about the science behind these vests’ capacity to stop bullets, even though we have explored the substances that give them their life-saving properties. In our pursuit of security, this scientific knowledge constitutes the subsequent level of comprehension.

How Do Bulletproof Vests Stop Bullets?

Ponder the moment a bullet races towards its target; it’s the intricate design of bulletproof vests that stands between life and a dire outcome. The multi-layer construction of these vests, sometimes called body armor, allows them to deflect and absorb bullet impact.

- Layering system: Multiple layers of high-strength fibers create a web that blunts the bullet, spreading its force over a larger area.

- Soft vs hard armor: Soft armor is typically made from woven fibers like Kevlar, while hard armor consists of metallic or ceramic plates.

- Trauma plates: Often added to soft armor, these plates enhance protection against higher-caliber bullets.

Soft Armor’s Role

Soft armor, crafted from materials like Kevlar or Twaron, is remarkable for its ability to transform the brute force of a bullet into a broader, less harmful impact. This fabric, woven into a net-like structure, catches the bullet in flight, much like a catcher’s mitt halts a fast-pitched ball.

Hard Armor’s Might

In contrast, hard armor brings forth materials such as steel, ceramic, or polyethylene to the fray. The plates serve as an impenetrable barrier that stops the relentless barrage of bullets, no matter how powerful they are.

Trauma Plates: A Powerful Barrier

The backbone of the vest’s defense, particularly in places that are susceptible to high-impact rounds, are the trauma plates. In chaotic times, they are the extra set of eyes that help keep everyone calm.

The components and their functions of a bulletproof vest are as follows:

| Material Type | Role in Vest | Protection Level |

| Kevlar/Twaron | Absorb impact; disperse force | Soft armor |

| Steel | Deflect bullets; prevent penetration | Hard armor |

| Ceramic | Break up bullet on impact | Hard armor |

| Polyethylene | Lightweight; high-impact resistance | Hard armor |

With its strong defense and excellent mobility, Kevlar has been a reliable companion in the realm of bulletproof vests for many years. Data shows that Kevlar vests have prevented the deaths of thousands of people due to their remarkably effective protection.

Keep in mind that bulletproof vests are more than just a combination of cloth and plates as we navigate their complex terrain. Years of research went into their design, and the result is protection that is second to none. Because of this, Bullet Proof Supply Store displays a vest that offers Level IIIA protection for $9, making sure that safety is affordable for everyone.

Now picture this: technological progress keeps on the rise, and soon we will have materials that are impervious to bullets while simultaneously offering unmatched comfort and flexibility. Think about the unrealized potential of new materials and technology that could change our perception of what is considered impenetrable as we plan for the future of body armor.

The Evolution of Bulletproof Vest Materials

From the days of combat, where warriors donned chainmail, to today’s sleek vests, the journey of bulletproof vest materials has been a remarkable evolution. Initially, vests were crafted from silk and nylon, but with advancements in technology, body armor now employs cutting-edge synthetic fibers.

- Silk and Nylon: The early 1900s saw vests made from layers of silk. Though somewhat effective, they were costly and failed under high-velocity bullet impacts.

- Kevlar®: The 1970s brought a revolution with the invention of Kevlar®, a synthetic fiber with remarkable strength and flexibility, becoming the standard in vest materials.

- Ultra-high-molecular-weight polyethylene (UHMWPE): A newer addition, this material offers high strength-to-weight ratios, crucial for modern body armor.

New studies highlight the possibilities of graphene composites and nanomaterials, which can radically alter the industry due to their exceptional lightweight and strength. These materials might soon leap from the lab to the frontline, offering protection like never before.

| Year | Material | Notes |

| The early 1900s | Silk | Expensive and not bulletproof against high-velocity rounds |

| 1970s | Kevlar® | Began the modern era of bulletproof materials |

| 2000s | UHMWPE | Improved strength-to-weight ratio for modern vests |

In a world where danger lurks around many a corner, the Bullet Proof Supply Store stands as a bastion of security. With products like their Level IIIA bulletproof vest, which can halt a .44 Magnum in its tracks, safety becomes accessible. At only $299, it serves as both protection and a showcase for the wonders of material science.

As we consider the future of bulletproof materials, we anticipate a time when vests are even more lightweight and robust, offering protection so seamless, that it feels like a second skin. This future beckons, promising a new chapter in the chronicles of personal defense.

And it’s not just about the vest itself; it’s about the peace of mind it brings, knowing you’re cocooned in the latest defense technology. Whether you’re a brave first responder venturing into dangerous situations or just someone looking for a little more security in this crazy world, these vests are a symbol of hope and a shield from the unknown.

Let us not lose sight of the progress we have achieved in the fight for safety as we prepare for the dangers of the future. The materials we’ve discussed not only shield but also signify human ingenuity’s triumph over adversity. Soon, we might see a time when the materials that once graced science fiction find their home in the very fabric of our protective gear, safeguarding lives with their resilient embrace.

Standards and Testing for Bulletproof Vests

Ever wonder what keeps a bulletproof vest from being pierced by a bullet? Sticking to strict guidelines and passing difficult exams are the name of the game. These vests are designed to protect lives, and you could think of them as silent guardians.

To start, bulletproof vests rely on a set of guidelines known as NIJ standards. These are the benchmarks, set by the National Institute of Justice, that a vest must meet to be considered effective.

- The testing process for certification is no walk in the park. It involves shooting the vest with various calibers to ensure it can withstand the impact. Imagine the tension in the air as each round makes contact, a true trial by fire.

- User safety is at the heart of compliance. Without these standards, there’s no guarantee a vest will hold up when it truly matters. It’s the difference between a vest you can trust and one you can’t.

You might be imagining these tests as exciting action sequences, like something out of a blockbuster movie, with sparks flying and dramatic music. But it’s a controlled, no-nonsense procedure, all to make sure the vest does its job when the stakes are real.

Material Matters

Here’s a quick look at what goes into these life-saving garments:

| Component | Function |

| Kevlar® | Absorbs impact, disperses bullet’s energy |

| Twaron® | Similar to Kevlar, offers heat resistance |

| Spectra® | Ultra-high-molecular-weight polyethylene, helps reduce vest weight |

| Ceramic Plates | Adds extra protection against higher-caliber rounds |

Each layer of fabric, every stitch, and strap, is meticulously designed to catch and spread out the force of a bullet, much like a goalie catching a high-speed puck.

List of Essential Elements

- Kevlar®, the star of the show, is renowned for its strength and has saved countless lives.

- Twaron®, a cousin to Kevlar, brings heat resistance to the table.

- Spectra® fibers keep the vests as light as possible because no one should feel weighed down when it comes to safety.

- Ceramic plates are the reinforcements, stepping in when threats escalate.

Once you have a better grasp of the materials and standards that constitute bulletproof vests, you might be amazed by the technology. It’s an impressive achievement to transform rough, durable materials into something that can envelop a person and prevent harm. Knowing your vest is up to standard can be very comforting for individuals seeking safety, whether it’s because of a dangerous job or just a desire for peace of mind.

When thinking about this barrier that bulletproof vests provide, keep in mind that there are different levels of protection. Everyday life throws us curveballs, but extreme situations call for more serious attire. When people have multiple layers of protection, they can rest easy knowing that they are well-prepared for anything life throws at them.

The Bullet Proof Supply Store is devoted to providing this kind of guarantee by stocking durable vests and supplies that combine scientific knowledge with survival techniques. Their products and services go above and beyond to guarantee that every client receives trustworthy security without breaking the bank.

Feel the difference with our modular front panel for the QRF plate carrier. It will give you more insight into bulletproof gear and help you find the right fit for your needs. Choosing this product is more than just a transaction; it’s an investment in your peace of mind.

Different Levels of Protection in Bulletproof Vests

Bulletproof vests, also known as body armor, come in various levels of protection. Each level is designed to protect against specific types of threats. Different types of threats are addressed at each level. The NIJ establishes these standards as a globally recognized benchmark for the effectiveness of body armor.

Define the NIJ protection levels from IIA to IV: The NIJ levels range from IIA (the least protection) to IV (the highest protection). Level IIA vests are typically lighter and more flexible, designed to stop lower velocity bullets such as 9mm and .40 S&W. As you move up in levels, the vests can withstand heavier and faster projectiles. The highest, Level IV, can protect against armor-piercing rifle rounds.

Compare the materials and construction differences between these levels: The core materials for bulletproof vests include Kevlar, Twaron, Spectra Shield, and Dyneema. These synthetic fibers are best known for their strength-to-weight ratio, providing amazing stopping power without excessive bulk.

- Level IIA vests often use lighter, thinner layers of these materials.

- Level II vests have more layers, hence they’re a bit thicker and heavier.

- Level III vests incorporate additional materials or plates made of steel or ceramic to handle rifle rounds.

- Level IV vests possess the thickest and heaviest armor plates, providing maximum protection.

Discuss the practical considerations for choosing the appropriate protection level: Your choice of vest level should reflect the potential threats you expect to face. Law enforcement officers might opt for Level II or IIIA, offering a balance of protection and comfort. Military personnel or those in high-threat environments may require Level III or IV vests for protection against rifle rounds.

Practical Considerations: – Comfort vs. Protection: Heavier vests offer more protection but may limit mobility. – Climate: Thicker vests can be hot, especially in warm climates. Job Requirements: Certain professions may dictate the level of protection needed. Budget: Higher levels of protection typically come at a higher cost.

Table: Comparison of Bulletproof Vest Materials by NIJ Level

| NIJ Level | Materials Used | Bullet Types Stopped |

| IIA | Kevlar, Twaron | 9mm, .40 S&W |

| II | Kevlar, Dyneema | 9mm, .357 Magnum |

| III | Kevlar, Plates | 7.62mm Rifle Rounds |

| IV | Ceramic Plates | Armor-piercing rounds |

When considering body armor, one must weigh these variables carefully. Additionally, certain vests can be augmented with plates to elevate their protective capabilities. A vest that halts a .44 Magnum at close range could save a life, and statistics show a significant number of individuals survive potentially fatal incidents when properly equipped with a vest.

Regarding the care of these vests, one must be diligent. They will need regular maintenance and upkeep to retain their protective qualities. For instance, consider storage. Vests should be kept flat, out of direct sunlight, and in a dry environment to prevent degradation. Regular inspections for wear and tear, ensuring the ballistic panels are properly situated, and following the manufacturer’s cleaning instructions are essential to prolong the life of the vest. By following these steps, you can keep your gear in top shape and be prepared to defend yourself at the highest level when it matters.

Caring for and Maintaining Bulletproof Vests

Bulletproof vests are your shield in dangerous situations, and just like any armor, they need regular maintenance to function properly. Here’s how you can ensure your vest remains in top condition:

- Store your vest in a cool, dry place to prevent the materials from degrading.

- Avoid folding or crushing the vest, as this can damage the fibers and reduce its effectiveness.

Impact of Wear and Tear

With time, bulletproof vests can show signs of wear and tear. This natural deterioration can affect the vest’s protective abilities. Regular inspection for rips, burns, or unusual odors can indicate it’s time for replacement. Experts suggest a bulletproof vest should be replaced every five years, or sooner if it’s been compromised.

Lifespan Considerations

The materials used in bulletproof vests, such as Kevlar or Dyneema, have a finite lifespan. Factors like exposure to UV light, moisture, and physical stress can shorten this span. It’s crucial to follow the manufacturer’s guidelines for care to maximize the vest’s lifespan.

List of Maintenance Tips

Here are some actionable steps to help keep your vest in peak condition:

- Inspect your vest regularly for signs of damage.

- Clean it carefully according to manufacturer instructions.

- Conduct a thorough check after any situation where the vest is hit or damaged.

Detailed Maintenance Table

| Action | Frequency | Purpose |

| Visual Inspection | After each use | 9mm, .40 S&W |

| Cleaning | As needed | 9mm, .357 Magnum |

| Storage Check | Monthly | 7.62mm Rifle Rounds |

| Professional Inspection | Annually | Armor-piercing rounds |

| Replacement | Every 5 years | Replace to ensure maximum protection |

Remember, your safety could depend on the condition of your vest. Avoid sloppy upkeep at all costs. Consider the care you’ve been giving your safety equipment as we are near the end of this section. Maybe you’ve forgotten something or didn’t think it was that important.

Maintaining your vest properly is essential; it’s like having a sentry on duty to ensure your safety. We will subtly guide you toward learning more about this topic, but the next step in guaranteeing your safety is to comprehend the complete capabilities of your protective gear.

In this context, you might consider visiting the Bullet Proof Supply Store for modular front panels for QRF plate carriers which can add an extra layer of protection to your gear.

If you want to know more about how bulletproof vests are made, there’s a lot of information available. Materials and engineering for these life-saving garments can be better understood with the help of resources like BulletSafe.

Conclusion

We at Bullet Proof Supply Store understand how seriously you take the matter of your safety. What keeps you safe are the materials we use to make our vests. What you see here is more than meets the eye; it is state-of-the-art technology crafted to alleviate anxiety. Having the correct armor is crucial whether you’re a law enforcement officer, posted in an uncertain location, or just trying to be ready for anything.

Innovation in protective gear is something we’re hell-bent on pursuing at all costs. Remember the significance of keeping your vest in good repair at all times and do your best to keep yourself informed and prepared. We solemnly pledge to prioritize your safety above all else.

Key Takeaway Keep in mind that the vest you’re wearing is an embodiment of the time and effort put into scientific research; it’s more than just a shield. Embrace the confidence it gives you and arm yourself with the skills to make the most of it. Just give us a call if you need any help or have any questions. Shop with assurance at Bullet Proof Supply Store, where you’ll find the finest in the business backing your gear.

Frequently Asked Questions about What are Bulletproof Vests Made of

What materials are used in the construction of bulletproof vests?

Most bulletproof vests are crafted from high-strength fibers that are known for their remarkable ability to absorb energy. The majority of the materials are composed of UHMWPE fibers, such as Kevlar, Twaron, Spectra, Dyneema, and others. To lessen the likelihood of damage from a bullet, these materials are selected for their capacity to deflect its impact.

How does Kevlar work in bulletproof vests?

Kevlar is an exceptionally durable synthetic fiber due to its high tensile strength-to-weight ratio. Bulletproof vests are constructed by interweaving multiple layers of Kevlar fabric to create a web-like structure. This structure can deform and absorb bullets, allowing them to impact a larger area. This procedure reduces the impact force of the bullet, making it unable to penetrate the vest.

Are steel or metal plates used in bulletproof vests?

Some bulletproof vests do feature hard armor, which consists of steel or other metal plates. Unlike Kevlar, which is a softer material, these plates are designed to withstand more powerful threats, like rifle rounds. Combinations of these metal plates and soft armor are common for maximum defense.

Can bulletproof vests also be stab-proof?

Unfortunately, not every bulletproof vest is impervious to stabbings. Bulletproof vests might not be enough to ward off blades and other pointed objects. Materials such as chainmail or specially woven fibers are used to make stabbing-proof vests. To provide protection against multiple threats, some vests are engineered to be bulletproof and stabproof simultaneously.

What is the difference between Level II and Level III body armor?

The degree of security they offer is what sets them apart. Lighter and specifically engineered to deflect lower-velocity projectiles, Level II body armor is ideal for use with handguns. The third level of body armor is designed to withstand threats with a higher velocity, such as rifles, and is heavier in construction. The US National Institute of Justice (NIJ) determines what constitutes an adequate level of protection.

How often should a bulletproof vest be replaced?

The durability of a bulletproof vest is determined by the materials utilized and the environmental factors it is subjected to. Manufacturers usually recommend that the protective fibers have a lifespan of 5 years when used normally. Nonetheless, to ensure the highest level of protection, it is necessary to examine and, if necessary, replace any vest that takes a bullet hit or is subjected to harsh environments.

Can bulletproof vests be legally purchased by civilians?

Anyone who is not a convicted felon can legally buy and wear a bulletproof vest in the US and most other countries. Check local laws before buying, though, because certain jurisdictions may have particular restrictions or regulations.

What is the weight of a typical bulletproof vest?

A bulletproof vest’s weight is proportional to its protection level and the materials utilized to create it. Vests with hard armor plates can weigh twenty pounds or more, whereas soft armor vests can weigh as little as two or three pounds.

How are bulletproof vests tested for effectiveness?

Certified labs employ standardized procedures established by groups such as the National Institute of Justice (NIJ) in the US to evaluate bulletproof vests. To make sure the vest doesn’t go over certain limits, these tests include shooting it with certain kinds of ammunition and then measuring the impact force.

Does temperature affect the performance of bulletproof vests?

Bulletproof vests, especially those constructed of Kevlar or similar materials, may not function as intended in very hot or cold weather. Over time, fibers can deteriorate in hot climates and become more brittle in cold ones. Bulletproof vests should be stored and maintained following the instructions provided by the manufacturer to guarantee their efficacy.