Bulletproof clothing, also known as ballistic or bullet-resistant clothing, is designed to protect the wearer from firearm projectiles and shrapnel. To guarantee the garments offer sufficient protection while still being comfortable to wear, several critical processes and materials are utilized throughout the manufacturing process.

Domestic terrorism, mass shootings, violent attacks, smash-and-grab thefts, and more are all on the rise, bringing greater awareness regarding the need for enhanced personal protection, including discreet bulletproof clothing.

Today, bulletproof clothing has gone mainstream, and along with this increase, in popularity has come to a multitude of questions from the general public as to how bulletproof clothing is made.

In this guide, we’ll take a look at the manufacturing process of bulletproof clothing and examine the materials that go into making it. By the time you’re done, you’ll have gained a much clearer picture of how clothing items like a bulletproof hoodie are made to protect you and the ones you care about most.

How Are Bulletproof Vests Made?

From choosing the materials to the last assembly, there are several steps in the production of bulletproof clothing. The process of making bulletproof clothing is detailed here:

1. Material Selection

When crafting bulletproof apparel, choosing the right materials is the first and most important step. The materials that are most often used are these:

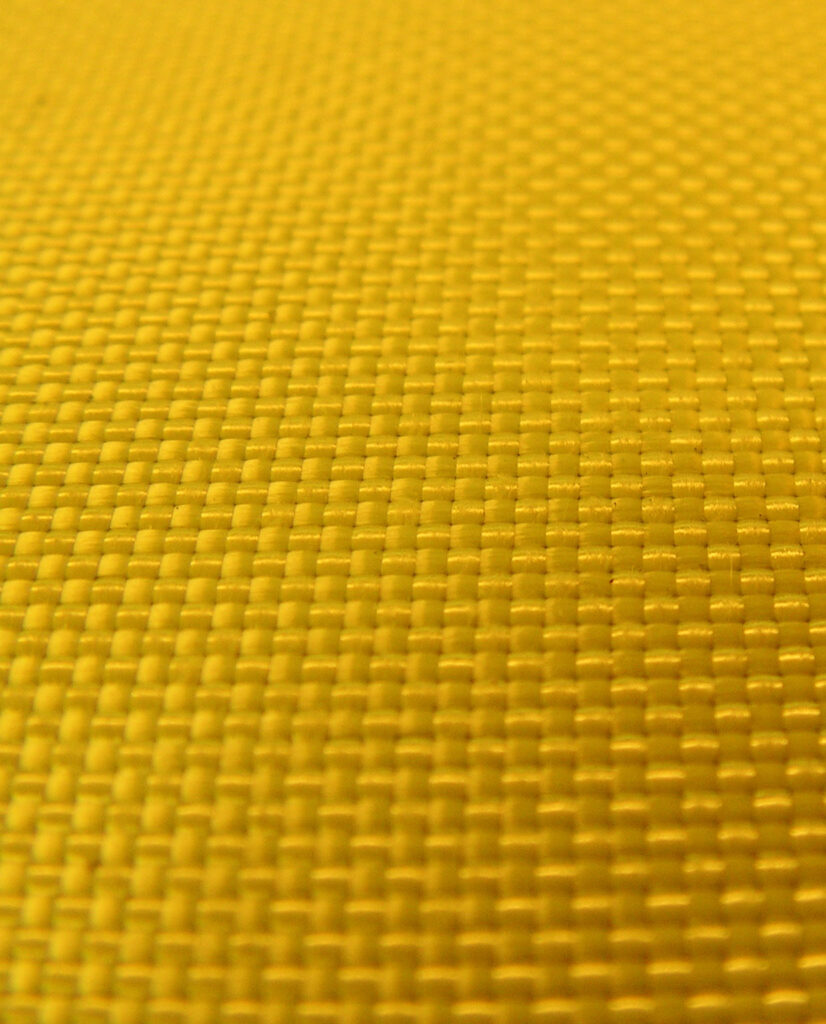

Aramid (Poly-para-phenylene terephthalamide) Fibers: Bulletproof garments often make use of aramid fibers, which are robust synthetic fibers. These fibers can efficiently absorb and disperse the energy of bullets because they are lightweight, durable, and possess a high tensile strength.

Ultra-High-Molecular-Weight Polyethylene (UHMWPE): Another material often used is UHMWPE, which is lighter than aramid fibers but offers similar protective properties. It’s a typical component of premium or specialty bulletproof apparel.

Dyneema: Bulletproof clothing is made with Dyneema, a kind of ultrahigh-molecular-weight polyethylene (UHMWPE) fiber that is famous for its great strength-to-weight ratio. Read this article to find out how Dyneema is used in bulletproof clothing.

Ceramic or Metal Plates: Protect yourself from higher-caliber rounds with bulletproof vests and other bulletproof apparel that feature hard armor plates made of composite materials, steel, or ceramic. These plates are essential for providing better protection in risky environments.

2. Layering the Fabric

The protective panels are constructed by layering the chosen materials. The necessary degree of protection will dictate the type of material and the quantity of layers. Stitched or laminated together, these layers form a resilient but pliable barrier that can deflect and absorb bullet impact.

3. Shaping and Cutting

Panels for vests, jackets, or other garments can be cut from the layered material. At this point, accuracy is paramount for a proper fit and complete coverage by the garment.

4. Assembly and Sewing

The finished garment is made by assembling and sewing together the cut pieces. The use of robust sewing machines that can manage thick, multi-layered textiles is commonplace in this process. The seams are given extra care, so they don’t become weak spots in the garment.

5. Adding Additional Features

Extra features like armor plate pockets, Velcro straps, or zippers can be incorporated into the design. With these additions, the user can modify the garment’s fit and adjust the amount of protection it provides.

6. Quality Control and Testing

Strict testing is carried out on bulletproof clothing before it is made available for purchase. To test the garment’s protective capabilities, it is necessary to fire different kinds of ammunition at it. Additionally, the apparel needs to be ballistic resistant according to NIJ standards. For more information on NIJ standards, click here.

Why Choose Bulletproof Clothing?

With this newfound knowledge about bulletproof clothing construction, you can shop with peace of mind knowing that we have the perfect bulletproof apparel to suit your needs. If you work in law enforcement, are a member of the military, or just want to be safe, bulletproof clothing is a great option.

Making Bulletproof Clothing: Final Thoughts

We hope that your question – how is bulletproof clothing made? – has been properly answered. A lot of thought and precision goes into making bulletproof clothing, from choosing high-tech materials to using exacting assembly techniques. Whatever the material—aramid fibers, UHMWPE, or something else entirely—each item is purpose-built to provide top-notch protection without sacrificing practicality or comfort.

Now that you know how bulletproof clothing is made, you can feel more confident and secure while exploring our collection of bulletproof clothing at Bullet Proof Supply Store to find the perfect gear for your needs. You can confidently take on any challenge when you have the proper protective gear.